Salient features

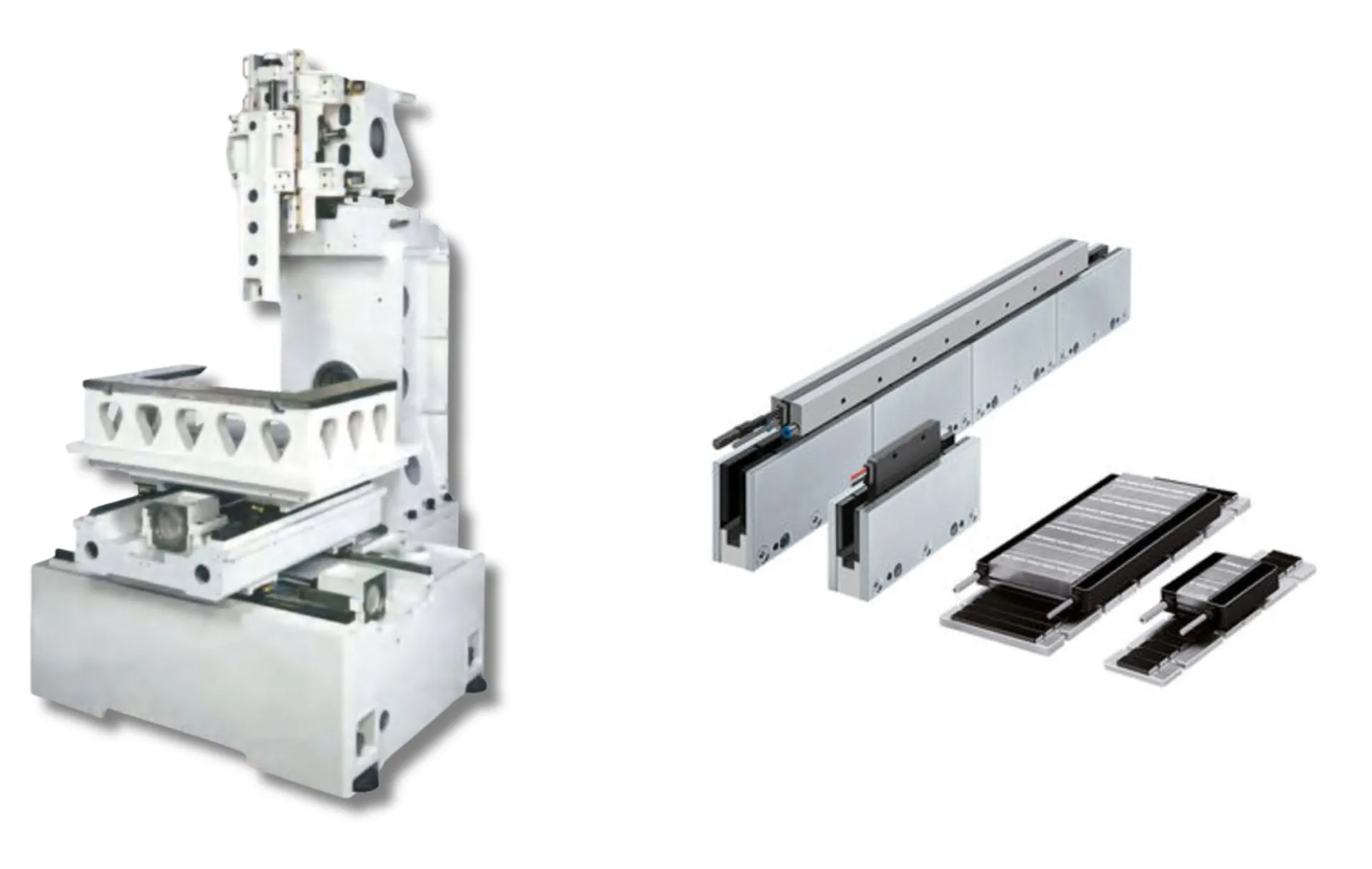

1. The mechanical body is cast with T-shaped high-rigidity cast iron

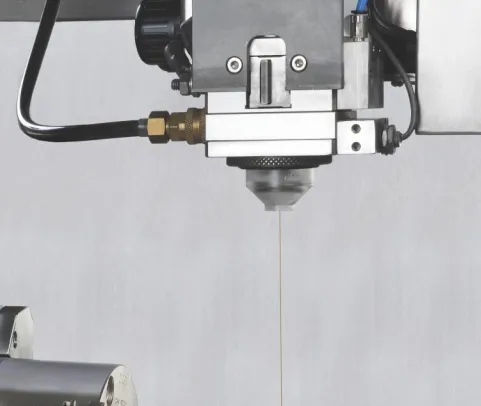

Automatic threading

The machine has a stable and high-speed automatic threading system

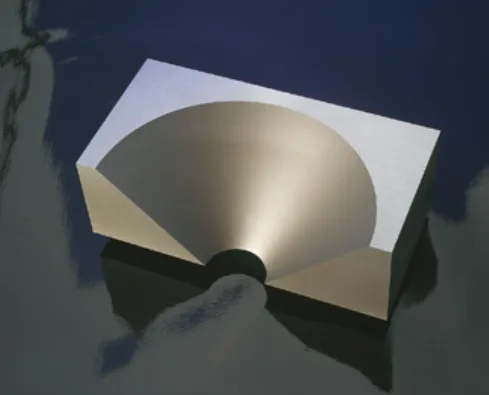

Maximum taper angle

The machine can process large taper angles with a maximum taper angle of +/- 15° /80mm

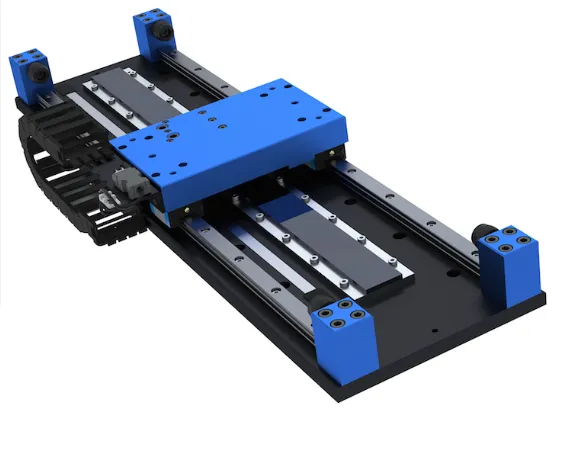

Linear motor

X, Y axes are driven by precise and durable linear motor

Connect

Use a USB drive for data access or an RJ-45 . network data access connection

* Windows is a popular operating system that provides users with a simple and easy-to-use interface.

* This is the software used to manage the system as well as all other application software running in the system. It is considered the "core" part used to interact directly with the hardware, and also a library so that programs can manage and adjust the system.

| Wire Cutting Machine specifications | |

|---|---|

| Travel axis X/Y | 1200x700 (mm) |

| Axis U/V | 150x150 (mm) |

| Axis Z/W | 500 ( submerged 495) (mm) |

| Maximum machining part size | 1700x1170x495 (mm) |

| Maximum workpiece load | 5000kg |

| Machine Dimensions WxDxH | 4558x3558x2500 (mm) |

| The height of the workbench from the ground | 995-1030 (mm) |

| Maximum jog speed | 1000.0mm/min |

| Machinable Wire Diameter | 0.15-0.3 (mm) |

| Spool maximum load weight | 10.0kg |

| Wire tension | 0.3-2.2kg |

| Maximum wire running speed | 220mm/s |

| Maximum taper processing angle | ±15°/80mm (large nozzle) |

| Mechanical weight | 10000kg |

| Mechanical color | White, organge |

| Maximum Power Consumption | 15KVA |

| Supply tank capacity | Submerged/2500L |

| Processing tank | Submerged/1000L |

| Filter type | Replaceable paper filter |

| Water resistance | Water tank containing ion filter tank |

| Filter tank capacity | Submerged /14L |

| Water temperature control | External cooler |